( ESNUG 540 Item 3 ) -------------------------------------------- [05/16/14]

Subject: Bernard Murphy's 47 quick low voltage RTL design tips (Part I)

> In this ESNUG post I wish to examine how the recent trend of dropping the

> on-chip voltage (VDD) -- to cut power -- ripples throughout every stage

> of chip design. Simply put:

>

> Power == (Voltage^2) / Resistance

>

> That is, as a chip's VDD drops linearly, power use drops geometrically.

>

> What follows are the nuances of how dropping to ultra-low voltages (to

> save on power, and while still maintaining performance over a range of

> temperatures) impacts how our chips are designed.

>

> - Jim Hogan

> Vista Ventures, LLC Los Gatos, CA

From: [ Bernard Murphy of Atrenta ]

Hi, John,

Here's a quick brain dump of all of the clever pre-silicon logic design and

architecture tricks I know that engineers use to cut power. I'm pretty sure

I can't do this topic complete justice, but I'll give it my best shot.

---- ---- ---- ---- ---- ---- ----

LOW VOLTAGE / LOW POWER FROM THE TOP

The bird's-eye view - topics relevant to low power/low voltage design:

- Power estimation (you can't optimize what you can't measure,

here pre-silicon)

- Use of mixed threshold voltage (Vt) libraries

- Clock-gating to reduce dynamic power

- What gating means for clock generation and the clock tree

- Voltage and frequency scaling to reduce dynamic power in

performance-insensitive sections of logic

- Power gating and biasing to reduce leakage power

- Power management support in IPs -- memories, CPUs, GPUs,

and others

- Describing and implementing all of this power intent

- Architecture tricks

- Power state switching in hardware and software

- Near/sub-threshold operation

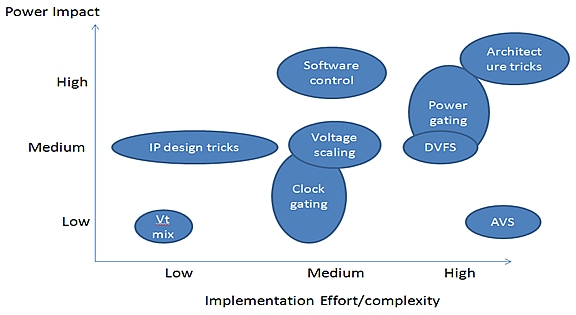

Below, I have a gross qualitative comparison of these techniques in terms of

effort vs impact. These terms are relative -- "low impact" does NOT mean it

is NOT worth doing -- it just means that it gives less return vs. the other

techniques. "High effort" means that you'll need to put a lot of work in to

get the desired impact.

Fig 1: Implementation Effort vs. Complexity

Based on what we see at Atrenta, Vt mix and clock-gating are widely used.

The other techniques are still in early stages of adoption except for very

large consumer-oriented chips such as application processors (TI OMAP,

Qualcomm SnapDragon and others that shall be legally nameless).

---- ---- ---- ---- ---- ---- ----

ESTIMATION

Power estimation is, well, an estimate. The further away you get from

implementation, the less accurate it becomes. Claims are made for Synopsys

PrimeTime-PX (a gate-level estimator and the defacto standard) getting to

within 5% of final silicon power -- though these are often challenged by

complex system behavior and any applications (such as differential power

analysis) which need to understand power as a cycle-level function of time.

In theory, SPICE simulations with layout parasitics would be the best

possible solution, but that's wildly impractical for SoC modeling.

So focus above the gate-level is based on relative guidance -- "is this

implementation better than that?" -- and not so much on absolute accuracy.

That said, you should be able to get RTL-based estimates within 15-20% of

silicon. These tools (our Atrenta SpyGlass Power and Ansys Power Artist

primarily) get highest accuracy using simulation dumps for activity power

estimation. You can also estimate based on "estimated activity" -- but

there you have estimation squared -- which is further reduced in accuracy.

All of these RTL power estimation methods are really for IP and small design

power estimation -- they're limited primarily by tool capacity and how

(un-)representative a simulation can be for modeling a realistic power use.

---- ---- ---- ---- ---- ---- ----

Another method to get to full-chip power estimation is use HW emulation.

1. run emulation,

2. dump all (or most) of the nodes,

3. compute power use based on that dump.

This works, but slows your emulation to a crawl because of the amount of

data it is dumping. Both Mentor Veloce and Cadence Palladium do this.

---- ---- ---- ---- ---- ---- ----

Beyond this, power estimation gets spooky. The most widely used tool for

estimating system power is the Excel spreadsheet. You provide measured power

for existing IPs, RTL or gate-level estimates for new IPs -- and then you

define "use-cases" for the chip which you think are representative of likely

consumer behavior (perhaps you wouldn't be making a phone call at the same

time you are playing Angry Birds, but you might want to browse the web while

you are calling). You then sum power over your active IP's per use-case.

Not exactly high-precision, but close to the state of the art today.

Fig 1: Implementation Effort vs. Complexity

Based on what we see at Atrenta, Vt mix and clock-gating are widely used.

The other techniques are still in early stages of adoption except for very

large consumer-oriented chips such as application processors (TI OMAP,

Qualcomm SnapDragon and others that shall be legally nameless).

---- ---- ---- ---- ---- ---- ----

ESTIMATION

Power estimation is, well, an estimate. The further away you get from

implementation, the less accurate it becomes. Claims are made for Synopsys

PrimeTime-PX (a gate-level estimator and the defacto standard) getting to

within 5% of final silicon power -- though these are often challenged by

complex system behavior and any applications (such as differential power

analysis) which need to understand power as a cycle-level function of time.

In theory, SPICE simulations with layout parasitics would be the best

possible solution, but that's wildly impractical for SoC modeling.

So focus above the gate-level is based on relative guidance -- "is this

implementation better than that?" -- and not so much on absolute accuracy.

That said, you should be able to get RTL-based estimates within 15-20% of

silicon. These tools (our Atrenta SpyGlass Power and Ansys Power Artist

primarily) get highest accuracy using simulation dumps for activity power

estimation. You can also estimate based on "estimated activity" -- but

there you have estimation squared -- which is further reduced in accuracy.

All of these RTL power estimation methods are really for IP and small design

power estimation -- they're limited primarily by tool capacity and how

(un-)representative a simulation can be for modeling a realistic power use.

---- ---- ---- ---- ---- ---- ----

Another method to get to full-chip power estimation is use HW emulation.

1. run emulation,

2. dump all (or most) of the nodes,

3. compute power use based on that dump.

This works, but slows your emulation to a crawl because of the amount of

data it is dumping. Both Mentor Veloce and Cadence Palladium do this.

---- ---- ---- ---- ---- ---- ----

Beyond this, power estimation gets spooky. The most widely used tool for

estimating system power is the Excel spreadsheet. You provide measured power

for existing IPs, RTL or gate-level estimates for new IPs -- and then you

define "use-cases" for the chip which you think are representative of likely

consumer behavior (perhaps you wouldn't be making a phone call at the same

time you are playing Angry Birds, but you might want to browse the web while

you are calling). You then sum power over your active IP's per use-case.

Not exactly high-precision, but close to the state of the art today.

Also for Excel spreadsheet analysis, it is common to run RTL or gate-level

simulations of your specific design blocks to get more accurate estimates.

---- ---- ---- ---- ---- ---- ----

By the way, if you are using 3rd-party IP, in the eval stage you have to

rely on the IP vendor to give you their "power model". This is a tricky

business. They don't want to give you an overly-pessimistic power model

before you buy, but there is no guarantee their model is representative of

the power usage you later find in your design. Today's fix is you work

very closely with the IP vendor to manage this -- and correct for surprises.

There are tools appearing in the system power space. They all expect you to

provide models for IP -- how you get those models is your problem. The same

applies to your "use-cases". You need to run whatever TLM, virtual model,

or emulation to come up with your realistic use-cases -- or you guess.

Docea is one example, built originally around application processor use-case

modeling, but it is now starting to see some interest in other areas. I see

a challenge for these tools over spreadsheets -- they don't solve the two

biggest problems: IP modeling and use-case development.

---- ---- ---- ---- ---- ---- ----

USING MIXED VT LIBRARIES

This has to be the most widely used and simplest technique, commonly called

MTCMOS, to reduce power. You typically have two cell libraries, one based

on low switching threshold (Vt) cells and the other based on high switching

threshold Vt cells.

Lower Vt cells switch faster, but suffer from higher leakage -- even in an

"off" state. High Vt cells run slower and have lower leakage.

When you synthesize your RTL, you give constraints to guide Design Compiler

or CDNS RTL Compiler to encourage timing-critical logic to be mapped to low

Vt cells and all other remaining logic to be mapped to high Vt cells. This

way you reduce overall leakage power. Your downstream P&R tools will take

care of the power details associated with these choices.

---- ---- ---- ---- ---- ---- ----

CLOCK-GATING

This is the next most widely used technique. The idea is simple -- a high

percentage of logic is inactive at any given time -- but your clock keeps on

triggering each register, even though nothing is changing on most of those

registers. If the clock is disabled on inactive registers, switching power

can be saved. Where and when you can gate a clock depends entirely on

system understanding, so this requires intensive designer input. Both SNPS

Power Compiler and CDNS RTL Compiler provide support for adding clock-gating

during RTL synthesis. You specify which registers should be gated and they

will insert the appropriate clock-gating around those registers.

Atrenta and Calypto (and to some extent Ansys) take this further. If you

know that the clock on a certain register can be gated, then it often

follows that upstream and downstream registers can also be gated, one cycle

earlier or later. It is also sometime possible to "strengthen" clock-

gating -- to keep your specific clock off for longer periods than initially

defined by the engineer -- by looking for stronger implications on the

gating logic. Tools like Synopsys Power Compiler are now clever enough to

automatically optimize clock-gating if given the right constraints.

Also for Excel spreadsheet analysis, it is common to run RTL or gate-level

simulations of your specific design blocks to get more accurate estimates.

---- ---- ---- ---- ---- ---- ----

By the way, if you are using 3rd-party IP, in the eval stage you have to

rely on the IP vendor to give you their "power model". This is a tricky

business. They don't want to give you an overly-pessimistic power model

before you buy, but there is no guarantee their model is representative of

the power usage you later find in your design. Today's fix is you work

very closely with the IP vendor to manage this -- and correct for surprises.

There are tools appearing in the system power space. They all expect you to

provide models for IP -- how you get those models is your problem. The same

applies to your "use-cases". You need to run whatever TLM, virtual model,

or emulation to come up with your realistic use-cases -- or you guess.

Docea is one example, built originally around application processor use-case

modeling, but it is now starting to see some interest in other areas. I see

a challenge for these tools over spreadsheets -- they don't solve the two

biggest problems: IP modeling and use-case development.

---- ---- ---- ---- ---- ---- ----

USING MIXED VT LIBRARIES

This has to be the most widely used and simplest technique, commonly called

MTCMOS, to reduce power. You typically have two cell libraries, one based

on low switching threshold (Vt) cells and the other based on high switching

threshold Vt cells.

Lower Vt cells switch faster, but suffer from higher leakage -- even in an

"off" state. High Vt cells run slower and have lower leakage.

When you synthesize your RTL, you give constraints to guide Design Compiler

or CDNS RTL Compiler to encourage timing-critical logic to be mapped to low

Vt cells and all other remaining logic to be mapped to high Vt cells. This

way you reduce overall leakage power. Your downstream P&R tools will take

care of the power details associated with these choices.

---- ---- ---- ---- ---- ---- ----

CLOCK-GATING

This is the next most widely used technique. The idea is simple -- a high

percentage of logic is inactive at any given time -- but your clock keeps on

triggering each register, even though nothing is changing on most of those

registers. If the clock is disabled on inactive registers, switching power

can be saved. Where and when you can gate a clock depends entirely on

system understanding, so this requires intensive designer input. Both SNPS

Power Compiler and CDNS RTL Compiler provide support for adding clock-gating

during RTL synthesis. You specify which registers should be gated and they

will insert the appropriate clock-gating around those registers.

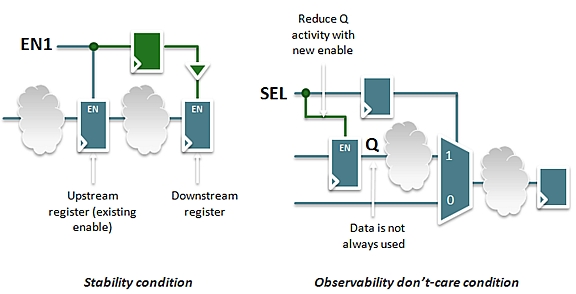

Atrenta and Calypto (and to some extent Ansys) take this further. If you

know that the clock on a certain register can be gated, then it often

follows that upstream and downstream registers can also be gated, one cycle

earlier or later. It is also sometime possible to "strengthen" clock-

gating -- to keep your specific clock off for longer periods than initially

defined by the engineer -- by looking for stronger implications on the

gating logic. Tools like Synopsys Power Compiler are now clever enough to

automatically optimize clock-gating if given the right constraints.

Fig 2: Two ways in which gating can be optimized vs. simple gating.

On the left a downstream register can also be gated (one cycle

later) because the upstream register has been gated. On the

right, a register can be gated under some conditions because

we can prove the register output will not be used under

those conditions.

On most chips, the power used around memory accesses is often a significant

percentage of overall chip power. Power here can be reduced by similar

techniques. For example, there is no need to clock data-in registers to a

RAM if write-enable to the memory is not active.

Fig 2: Two ways in which gating can be optimized vs. simple gating.

On the left a downstream register can also be gated (one cycle

later) because the upstream register has been gated. On the

right, a register can be gated under some conditions because

we can prove the register output will not be used under

those conditions.

On most chips, the power used around memory accesses is often a significant

percentage of overall chip power. Power here can be reduced by similar

techniques. For example, there is no need to clock data-in registers to a

RAM if write-enable to the memory is not active.

Fig 3: Data input register to a memory can be gated if write-enable

is not active.

Automated techniques like these can save 15% or more power in designs that

have not been carefully tuned by power experts. But they also highlight the

importance of ranking suggested optimizations vs. the estimated power saved,

based on realistic simulations. If a clock needs to turn on and off again

frequently with short periods in the off-state, adding gating logic may

actually increase power.

Fig 3: Data input register to a memory can be gated if write-enable

is not active.

Automated techniques like these can save 15% or more power in designs that

have not been carefully tuned by power experts. But they also highlight the

importance of ranking suggested optimizations vs. the estimated power saved,

based on realistic simulations. If a clock needs to turn on and off again

frequently with short periods in the off-state, adding gating logic may

actually increase power.

Another thing to watch out for with clock-gating tools -- you better make

sure the changes they make are CDC-safe. There was one notorious example

(I'm not naming names) which probably saved an impressive amount of power

but added lots of new synchronization problems to each design it optimized.

A designer I respect said it "generated evil" because he had to re-run CDC

and undo many of the changes this unnamed tool had made.

---- ---- ---- ---- ---- ---- ----

CLOCK TREE ISSUES

If you're thinking about clock gating, you should also be thinking about

clock generation and your clock tree. The gating I have described so far is

fine-grained or local. You can also consider coarse-grained or more global

gating; for example, gating the main clock input to an IP. The advantage of

coarse-grained clock-gating is you don't just save switching power in the

gates, you also save power in driving the clock sub-tree below that point.

In fact, if you are going to do coarse-grained gating, the higher in the

clock tree you can do that, the more power you will save. Deciding when and

where you can do this takes detailed design understanding and judgment.

If you are thinking about coarse-grained power control, it makes sense to

put clock generation logic and gating in one block near the generating

PLL(s). This might be a little counter-intuitive (you tend to think of

gating the IP clock at the IP), but if you are struggling to cut microAmps,

this can help. And anyway it's good design practice.

---- ---- ---- ---- ---- ---- ----

VOLTAGE & FREQUENCY SCALING

The simplest trick here is to run a part of the logic at a lower voltage if

your chip is not particularly performance critical. Synopsys and ARM derate

some of their memory IP down to 0.9 V for this purpose. Intel and AMD (and

other companies) run non-critical logic in low voltage islands. This is

often called static voltage scaling -- which is in contrast with dynamic

voltage scaling -- more commonly used in dynamic voltage and frequency

scaling (DVFS).

Another thing to watch out for with clock-gating tools -- you better make

sure the changes they make are CDC-safe. There was one notorious example

(I'm not naming names) which probably saved an impressive amount of power

but added lots of new synchronization problems to each design it optimized.

A designer I respect said it "generated evil" because he had to re-run CDC

and undo many of the changes this unnamed tool had made.

---- ---- ---- ---- ---- ---- ----

CLOCK TREE ISSUES

If you're thinking about clock gating, you should also be thinking about

clock generation and your clock tree. The gating I have described so far is

fine-grained or local. You can also consider coarse-grained or more global

gating; for example, gating the main clock input to an IP. The advantage of

coarse-grained clock-gating is you don't just save switching power in the

gates, you also save power in driving the clock sub-tree below that point.

In fact, if you are going to do coarse-grained gating, the higher in the

clock tree you can do that, the more power you will save. Deciding when and

where you can do this takes detailed design understanding and judgment.

If you are thinking about coarse-grained power control, it makes sense to

put clock generation logic and gating in one block near the generating

PLL(s). This might be a little counter-intuitive (you tend to think of

gating the IP clock at the IP), but if you are struggling to cut microAmps,

this can help. And anyway it's good design practice.

---- ---- ---- ---- ---- ---- ----

VOLTAGE & FREQUENCY SCALING

The simplest trick here is to run a part of the logic at a lower voltage if

your chip is not particularly performance critical. Synopsys and ARM derate

some of their memory IP down to 0.9 V for this purpose. Intel and AMD (and

other companies) run non-critical logic in low voltage islands. This is

often called static voltage scaling -- which is in contrast with dynamic

voltage scaling -- more commonly used in dynamic voltage and frequency

scaling (DVFS).

Fig 4: An example of power management configurations

DVFS is a clever technique where you switch both voltage and clock frequency

between a limited set of options, based on performance requirements. In one

mode where you need to run fast, you run at maximum voltage and frequency;

but at higher power. In another "sleepier" mode, you can run slower, at

lower voltage and frequency; so at lower power. Making these choices has

to be a combination of architect/designer know-how and power estimations to

gauge trade-offs.

DVFS has not been widely adopted except in very tightly controlled and

verified IP (ARM uses this method in CPUs) because it creates significant

added complexity in both implementation and verification. You have an IP

that can run at multiple frequencies, so you need synchronization into and

out of that IP. For your design flow, timing closure is more complicated

because you have to consider all corners across each possible frequency.

And in verification, you need to verify not just basic behavior, but also

the behavior at each frequency (perhaps a FIFO works fine at one frequency,

but overflows at another).

A related technique is Adaptive Voltage Scaling (AVS). This is generally

used to adjust for on-chip variation (OCV). Local monitors measure

ring-oscillator frequencies and adjust voltage in a local region to

compensate for process and temperature variation. This can be used to bring

timing back into spec, but also to reduce unnecessary overdrive, hence

power. This is a very advanced technique, typically used only in big

CPU designs since it adds to all of the above problems plus a new wrinkle;

getting design flow timing closure when you don't know how the AVS will

behave in any given case (making corner-case analysis very "interesting").

Fig 4: An example of power management configurations

DVFS is a clever technique where you switch both voltage and clock frequency

between a limited set of options, based on performance requirements. In one

mode where you need to run fast, you run at maximum voltage and frequency;

but at higher power. In another "sleepier" mode, you can run slower, at

lower voltage and frequency; so at lower power. Making these choices has

to be a combination of architect/designer know-how and power estimations to

gauge trade-offs.

DVFS has not been widely adopted except in very tightly controlled and

verified IP (ARM uses this method in CPUs) because it creates significant

added complexity in both implementation and verification. You have an IP

that can run at multiple frequencies, so you need synchronization into and

out of that IP. For your design flow, timing closure is more complicated

because you have to consider all corners across each possible frequency.

And in verification, you need to verify not just basic behavior, but also

the behavior at each frequency (perhaps a FIFO works fine at one frequency,

but overflows at another).

A related technique is Adaptive Voltage Scaling (AVS). This is generally

used to adjust for on-chip variation (OCV). Local monitors measure

ring-oscillator frequencies and adjust voltage in a local region to

compensate for process and temperature variation. This can be used to bring

timing back into spec, but also to reduce unnecessary overdrive, hence

power. This is a very advanced technique, typically used only in big

CPU designs since it adds to all of the above problems plus a new wrinkle;

getting design flow timing closure when you don't know how the AVS will

behave in any given case (making corner-case analysis very "interesting").

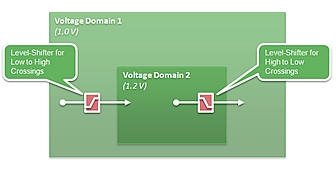

Fig 5: Level shifter and isolation logic needs

When a design has multiple voltage domains or is using DVFS, there will be

signals crossing between different voltage domains -- and that means logic

level shifters are required at least for the low voltage to higher voltage

transitions -- since otherwise a low voltage transition will likely be

insufficient to drive a transition on the high voltage side. (In theory,

you should do the same for high-to-low transitions, in practice we see these

are often being left out, since there usually isn't much of a problem in

overdriving, although there is some power cost).

---- ---- ---- ---- ---- ---- ----

BIASING & POWER GATING

Everything I have described so far, other than Vt mix, is primarily a method

to reduce dynamic power. Leakage power -- the power the device burns even

when it's not doing anything and all the clocks are turned off - is now a

significant component at smaller feature sizes, even more so when a lot of

time is spent in an idle state.

There are fab process ways to alleviate this (FinFET vs FD-SOI) which others

are more qualified to talk about than me. Biasing is another trick. By

changing the bias in the transistor body to something other than power or

ground, you can reduce leakage at the expense of reduced performance. You

can do this statically or dynamically. Also, not my area of expertise so

I'll defer to experts.

Power-gating is one of the most powerful (yeah, I said it) methods to reduce

leakage power. Here you don't just scale voltage -- you turn it off. Doing

this reduces not just dynamic power but also leakage power -- to zero. This

method has been used for many years in major processors, because they have

a lot of functionality that does not need to be on all the time. If you've

ever wondered what "dark silicon" is, this is it -- functions turned off

when not needed. We're now starting to see some interest beyond phone

chips. Wherever you have multiple functions, or a function with multiple

channels -- which do not need to all be on all the time -- you have an

opportunity for power-gating. We also see interest for chips which have

very low (micro-amp) standby power, where the bulk of the functionality is

turned off when not active and only a wakeup function of some kind is

always-on.

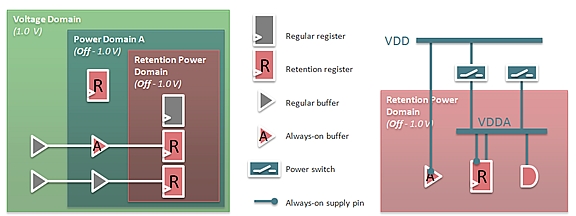

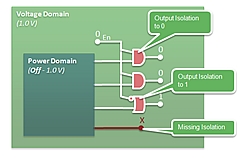

There are a couple of wrinkles to using power islands. First, when you

power down a block, you have to isolate it from downstream logic (don't want

floating outputs driving inputs to powered gates). Also, sometimes you

can't quite turn everything off. It might take as much power as you saved

to spin up to a ready state when you re-power the block. In these cases you

insert retention registers (or declare existing registers as retention

registers) which don't turn off when the block turns off. These hold

critical state from which the block can (relatively) quickly recover when

it turns back on.

Second, power and voltage islands create a new design problem not well

covered in power intent descriptions. Both techniques constrain physical

hierarchy, or at least they should. Power rails for a given domain should

ideally be contiguous -- it's wasteful at least in area to have many domains

with identical requirements scattered throughout the floorplan. Each will

require its own power rails and switches. But logic hierarchy is typically

not structured along power boundaries, especially since the power plan may

change quite a bit as the design evolves. In the old days, you would say

"No problem -- we can do all that hierarchy restructuring stuff in the

synthesis or place and route tool". But that was before power intent had

to be described in your RTL to drive P&R implementation downstream. Now you

have a circular dependency. You have to get the hierarchy right, so you can

describe the power intent you want, so you can implement it. If you try to

fix the hierarchy in implementation, your RTL power intent will be wrong --

you'll have level shifter and isolation logic in the wrong places for

example.

Fig 5: Level shifter and isolation logic needs

When a design has multiple voltage domains or is using DVFS, there will be

signals crossing between different voltage domains -- and that means logic

level shifters are required at least for the low voltage to higher voltage

transitions -- since otherwise a low voltage transition will likely be

insufficient to drive a transition on the high voltage side. (In theory,

you should do the same for high-to-low transitions, in practice we see these

are often being left out, since there usually isn't much of a problem in

overdriving, although there is some power cost).

---- ---- ---- ---- ---- ---- ----

BIASING & POWER GATING

Everything I have described so far, other than Vt mix, is primarily a method

to reduce dynamic power. Leakage power -- the power the device burns even

when it's not doing anything and all the clocks are turned off - is now a

significant component at smaller feature sizes, even more so when a lot of

time is spent in an idle state.

There are fab process ways to alleviate this (FinFET vs FD-SOI) which others

are more qualified to talk about than me. Biasing is another trick. By

changing the bias in the transistor body to something other than power or

ground, you can reduce leakage at the expense of reduced performance. You

can do this statically or dynamically. Also, not my area of expertise so

I'll defer to experts.

Power-gating is one of the most powerful (yeah, I said it) methods to reduce

leakage power. Here you don't just scale voltage -- you turn it off. Doing

this reduces not just dynamic power but also leakage power -- to zero. This

method has been used for many years in major processors, because they have

a lot of functionality that does not need to be on all the time. If you've

ever wondered what "dark silicon" is, this is it -- functions turned off

when not needed. We're now starting to see some interest beyond phone

chips. Wherever you have multiple functions, or a function with multiple

channels -- which do not need to all be on all the time -- you have an

opportunity for power-gating. We also see interest for chips which have

very low (micro-amp) standby power, where the bulk of the functionality is

turned off when not active and only a wakeup function of some kind is

always-on.

There are a couple of wrinkles to using power islands. First, when you

power down a block, you have to isolate it from downstream logic (don't want

floating outputs driving inputs to powered gates). Also, sometimes you

can't quite turn everything off. It might take as much power as you saved

to spin up to a ready state when you re-power the block. In these cases you

insert retention registers (or declare existing registers as retention

registers) which don't turn off when the block turns off. These hold

critical state from which the block can (relatively) quickly recover when

it turns back on.

Second, power and voltage islands create a new design problem not well

covered in power intent descriptions. Both techniques constrain physical

hierarchy, or at least they should. Power rails for a given domain should

ideally be contiguous -- it's wasteful at least in area to have many domains

with identical requirements scattered throughout the floorplan. Each will

require its own power rails and switches. But logic hierarchy is typically

not structured along power boundaries, especially since the power plan may

change quite a bit as the design evolves. In the old days, you would say

"No problem -- we can do all that hierarchy restructuring stuff in the

synthesis or place and route tool". But that was before power intent had

to be described in your RTL to drive P&R implementation downstream. Now you

have a circular dependency. You have to get the hierarchy right, so you can

describe the power intent you want, so you can implement it. If you try to

fix the hierarchy in implementation, your RTL power intent will be wrong --

you'll have level shifter and isolation logic in the wrong places for

example.

Fig 6: Example of grouping two power domains under a new

hierarchy to align with a common power intent for

those domains. Or conversely un-grouping two

domains which may have changed to being in different

power or voltage islands.

There are two ways out of this trap. One is to define the power hierarchy

up-front, before design -- and to forbid any changes beyond that point.

This can work if you can meet your power budget no matter what. But it

isn't practical if you are dealing with large 3rd-party IP (such as the

Imagination Tech GPUs) which must be partitioned for power to meet both a

reasonable budget and reasonable use-cases (you can't just switch the whole

thing on or off). The second approach it to use RTL restructuring. Atrenta

provides a general solution for this. There are other more specialized

solutions from companies such as Magillem.

---- ---- ---- ---- ---- ---- ----

This discussion is continued in part II.

- Bernard Murphy

Atrenta, Inc. San Jose, CA

---- ---- ---- ---- ---- ---- ----

Related Articles

Jim Hogan on how low energy designs will shape everyone's future

Hogan on how ultra low voltage design changes energy and power

Bernard Murphy's 47 quick low voltage RTL design tips (Part I)

Bernard Murphy's 47 quick low voltage RTL design tips (Part II)

Isadore's 28 low voltage timing sign-off & characterization tips

Trent's 12 tips on transistor and full custom low voltage design

Hogan on SNPS, CDNS, Atrenta, CLKDA, Solido as low voltage tools

Fig 6: Example of grouping two power domains under a new

hierarchy to align with a common power intent for

those domains. Or conversely un-grouping two

domains which may have changed to being in different

power or voltage islands.

There are two ways out of this trap. One is to define the power hierarchy

up-front, before design -- and to forbid any changes beyond that point.

This can work if you can meet your power budget no matter what. But it

isn't practical if you are dealing with large 3rd-party IP (such as the

Imagination Tech GPUs) which must be partitioned for power to meet both a

reasonable budget and reasonable use-cases (you can't just switch the whole

thing on or off). The second approach it to use RTL restructuring. Atrenta

provides a general solution for this. There are other more specialized

solutions from companies such as Magillem.

---- ---- ---- ---- ---- ---- ----

This discussion is continued in part II.

- Bernard Murphy

Atrenta, Inc. San Jose, CA

---- ---- ---- ---- ---- ---- ----

Related Articles

Jim Hogan on how low energy designs will shape everyone's future

Hogan on how ultra low voltage design changes energy and power

Bernard Murphy's 47 quick low voltage RTL design tips (Part I)

Bernard Murphy's 47 quick low voltage RTL design tips (Part II)

Isadore's 28 low voltage timing sign-off & characterization tips

Trent's 12 tips on transistor and full custom low voltage design

Hogan on SNPS, CDNS, Atrenta, CLKDA, Solido as low voltage tools

Join

Index

Next->Item

|

|