( ESNUG 539 Item 5 ) -------------------------------------------- [05/08/14]

Subject: 15 gotchas found in Design and IP data management tools (part II)

From: [ Dean Drako of IC Manage ]

Hi, John,

The items 5 to 15 here below in this (part II) are the deep details of

a DM system.

5. Bug Dependency Management

6. IP Reuse Support

7. Project Management & Status Reporting

8. Check-List Driven Acceptance Flow

9. Linking/Importing IP & Design Data From Other Systems

10. Properties Encapsulated In IP

11. Global Data Consistency / Local Caching

12. Metadata Consistency / Reliability

13. Atomic Transactions

14. R&D Continuity Despite Remote Network Disruptions

15. Granular Security

I advise reading (part I) the "nuts and bolts" in ESNUG 539 #4 before

reading these details.

- Dean Drako

IC Manage Campbell, CA

---- ---- ---- ---- ---- ---- ----

5. BUG DEPENDENCY MANAGEMENT

Bug dependency management is the ability to identify the impact of a bug or

bugs across shared, reused, and derived design components.

DM integration with bug tracking systems

HW development teams track bugs and bug fixes using various 3rd party tools

such as Jira, Bugzilla, or internally developed systems.

Integration between a bug tracking system and a DM system ranges from no

integration, to unidirectional, or to full bidirectional linkage.

- Uni-directional DM/bug tracking integration, a binding is created

in the bug tracker to the set of files that were changed to fix a

particular bug, or ECO. This allows you to browse the bug data

within the bug tracking system and also see the file differences

for fixes that were applied to resolve them. However, the DM

system has no knowledge of the bug data.

- Bi-directional DM/bug tracking. The bugs and bug fixes associated

with each design element or IP block are automatically recorded in

both the bug tracking system and in the DM system. This means you

see the design information in the bug tracker along with the bug

and fix information in the DM system on a per file basis.

Further, the DM system records the bug information and binds it to

the file-tree state. This allows you to browse the bug data not

only within the bug tracking system, but also to perform workspace

synchronization for the different bug life cycle states directly

in your DM tool.

Bug tracing and Fix Propagation

I wrote about inter-file branching and bi-directional bug tracking in a

prior DeepChip letter in ESNUG 520 #3:

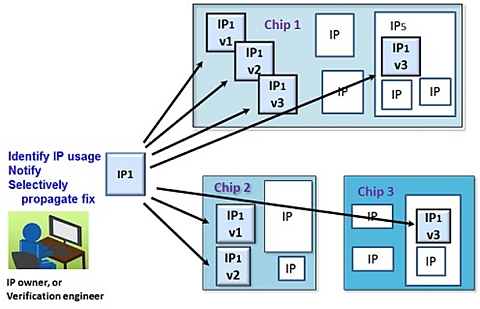

"Verification and design engineers view an IP with its design history

and bug history. If an engineer finds a bug, they can track through

the complete design history and be able to return the IP to an earlier

working state.

The verification engineer who finds a bug can immediately view all IP

instances and versions, what chips they are used in, and by which

engineers.

They can then send out an immediate notification regarding the bug to

all affected parties. This avoids the need for another team to later

repeat the same debugging process to find the identical bug.

The IP owner and verification engineer can also selectively auto-

propagate any fixes. The bug notification and fix is automatically

attached to the IP itself so that any future IP user can use it."

- from http://www.deepchip.com/items/0520-03.html

Controlled automation of these "bug interdependency management" steps can

also prevent inadvertently taping out with a known bug.

The alternative is to manually clone bugs for every derivative (or shared)

component.

---- ---- ---- ---- ---- ---- ----

6. IP REUSE SUPPORT

Our 2013 survey ESNUG 520 #1 showed that 44% of non-memory design involved

internal IP reuse. A company's ability to make its internal IP readily

available for reuse by all design teams is critical for competitiveness.

Splitting. A single IP repository (data storage location) allows your HW

design team to maintain the relationships between design files that would

otherwise be lost if split across multiple repositories. And although

splitting repositories is painful, unless your reuse database scales to

large file and directory accounts, 1000's of users, and 1,000,000's of

concurrent connections, splitting is inevitable to maintain functionality

and performance.

Tracing IP history. You maximize IP reuse if your DM system can trace where

your IP is being used across projects (designs-products), subsystems, and

by which users. Further, companies like to see how individual IP evolves

over time, in terms of design content and quality.

- A change-based DM system lets engineers see who made what changes

and to trace the history over time. For example, if someone

modified the IP, they may have changed it to a 32-bit bus, added

pipelining, and targeted a different process.

- A file-based systems makes duplicate physical copies of the IP.

The big drawback here you lose reliable, automated traceability.

The designer must first search the repository - or multiple

repositories - to find the IP copies, and then manually

determine the differences.

Searching for IP. Does your DM system publish your IP based on its

characteristics such as target process, power consumption, max frequency,

silicon validation, area? Can you also search using quality metrics like a

quality checklist status, passing functional verification, physical DRC/LVS

verification, number of open bugs, etc.?

---- ---- ---- ---- ---- ---- ----

7. PROJECT MANAGEMENT & STATUS REPORTING

In addition to managing your design data, engineering managers also want to

be able to track design activity. This requires first setting up your

project for efficient management (see "2. Configuration Management") and

then having visibility at the project/design-level to see what design

modules have been checked in and out, and how often.

Managers also want status reports and analysis, often daily. If the project

is not converging, they will then want more granular status reporting so

they can to drill down to determine which design/IP blocks are causing a

problem or project delay.

Does your DM system do this for you, and to what degree? Many DM systems

require groups to fill out spreadsheets manually to do status updates. This

in turn involves manual and error prone tasks of extracting up-to-date

information from already overburdened design team members.

One example of this that the U.S. Army, Navy, Air Force, and Marines each

have their own inventory systems for ammunition which can NOT share data

directly -- even though they have worked for decades to develop one single

database.

"A request for ammunition from the Marine Corps, for example, is

e-mailed to the Army. The e-mail is printed out and manually

retyped into the Army system because the services cannot share

data directly. Not only is this time consuming, but it can

introduce errors -- by an incorrect keystroke, for example."

- USA Today (04/28/14)

If the meta-data (e.g. revision data) in your DM system is captured in a

consistent, accurate way, your project leads will be happy. Why? Because

it means they can automatically generate reports and do trend analysis at

the top-level, plus readily see at a glance the project status of all IP

and subcomponents -- covering IP quality, open bugs and tapeout readiness.

They can even graph the trend of these metrics from version to version.

---- ---- ---- ---- ---- ---- ----

8. CHECK-LIST DRIVEN ACCEPTANCE FLOW

Last year's 2013 IP Reuse study ESNUG 520 #1 referenced a growing practice

for engineering groups to set up a formal process for IP development and

verification, with checklist items to track and monitor on each block; thus

tying the relevant status information of all the IP used to continuously

gauge the project's progress. A check list can apply to each stage of

design and verification to be passed.

These individual checklist guidelines can be enforced loosely or strictly,

depending on your company need. It can be for any design component.

This will encourage certain steps to be taken; for example, when a remote

design group checks in an IP, it's ready for a team at a different site and

time zone to use it the following day -- without schedule hits due to some

forgotten oversight. It also allows better quality control and visibility

into design progress, and correspondingly, the ability to assign resources.

Does your DM system directly integrate checklists? With automatic updates

tied to each design element? Or is it done outside the system by hand on

an Excel spreadsheet? And for for IP reuse: is the state of your design

checklist directly linked to the state of your IP, so that it's always

up-to-date?

---- ---- ---- ---- ---- ---- ----

9. LINKING/IMPORTING IP & DESIGN DATA FROM OTHER SYSTEMS

Our 2014 Design and IP Management survey (ESNUG 539 #1) showed that 55% of

companies have at least two different DM systems. Further, the majority

of those with multiple DM systems want better integration between them.

(One example is when a digital design team wants to use design elements

from the analog team.)

One approach to have different DM systems "talk" is to use a virtual tree

design. In such a system it is possible to perform multi-DM-system

configuration management by mapping individual DM system tree structures

into the virtual representation. Users can then register bindings into

the virtual object (protocol, authentication, tree structure, release info)

which allows users to pull content from multiple DM systems in a

transparent manner.

Another method is to manually copy your design data from your source DM

system and check it into your destination DM system. A drawback is that

designers then lose the link to the active design status, breaking the

audit trail.

---- ---- ---- ---- ---- ---- ----

10. PROPERTIES ENCAPSULATED IN IP

By encapsulating internal and 3rd party IP properties hierarchically and

organizing them in an easily searchable manner, everyone has immediate

access to all your IP's data, metadata, constraints and design history

all in one place. To encourage verification reuse, verification info

like testbenches, assertions and results, can also be encapsulated.

Because IP evolves dynamically over time -- often in parallel with chip

development -- it should be continuously updated.

Does your DM system allow you to encapsulate IP properties or design status

data? If yes, can it maintain the inherited hierarchy for the properties?

---- ---- ---- ---- ---- ---- ----

11. GLOBAL DATA CONSISTENCY / LOCAL CACHING

Global data consistency means everyone on the same project has access to all

versions of the same files plus its latest versions.

The way DM infrastructures try to get this desired result varies.

Mirrors. Some DM systems use mirrors -- or repository replicas -- for data

availability at remote sites. A drawback is that the mirrors can get out of

sync so that your master file content diverges from the remote site content;

that is, you get different results when trying to access the latest version

of a file.

With mirrors, there is an inherent synchronization overhead to ensure that

different teams get the same file version. The more mirror sites, the more

complicated this becomes and the greater the risk of error.

Caching. Some DM systems do global consistency by having a single server

maintain one global point of reference for versioned metadata and user

workspace contents. This type of DM system must use local caching to

deliver copies of design file data consistently and it must run quickly

across multiple sites.

The design file data is stored at remote sites in a local cache, while the

revision control metadata is stored at the master site. Remote queries to

the metadata should be fast since those involve a small number of network

packets. This approach also eliminates synchronization problems, even with

multiple servers.

---- ---- ---- ---- ---- ---- ----

12. METADATA CONSISTENCY / RELIABILITY

Does your DM system have a single distinct metadata repository that works

at both the IP and project level?

The goal of capturing metadata in a consistent way during design module

development is so your DM system can automatically generate reports and

trend analysis at the top level on down.

For DM systems without a centralized meta-data repository, the project

leader would need to query the status of individual files and workspaces,

which can be extremely time consuming.

---- ---- ---- ---- ---- ---- ----

13. ATOMIC TRANSACTIONS

Atomic transactions mean that all database updates associated with a given

design change are executed -- or none are. Atomic transactions prevent

inconsistent database states, for example, in case of a network disruption

where a subset of necessary updates are completed. Atomic transactions

prevent this from occurring.

Atomic transactions are necessary to prevent data corruption, which can be

painful to unravel and recover from.

Virtually all DM systems claim "transactions". However, for individual-file

based systems, which don't understand "transactions" for groups of files,

the concept of an atomic transaction, is confusing at best and difficult

to implement in a reliable and consistent manner.

---- ---- ---- ---- ---- ---- ----

14. R&D CONTINUITY DESPITE REMOTE NETWORK DISRUPTIONS

To maximize 24/7 productivity, it is ideal that designers at remote sites

are able to continue to operate productively within their project.

Distributed server architectures can tolerate transient network disconnects

to the corporate network because both metadata and data are available

locally at the remote site. It is possible to sync to the last replicated

file version, as well as perform checkouts of existing files if the

connection to the central server is lost. Once the network connection is

restored, version records are automatically re-synchronized to prevent

data corruption and version conflicts.

---- ---- ---- ---- ---- ---- ----

15. GRANULAR SECURITY

From our survey this year, security issues with file-based DM systems were

a factor for 69% of designers. Companies want to protect their key assets

such as trade secrets and IP -- plus conform to export restrictions.

On security issues, a fundamental difference between DM systems is whether

your data is controlled at one central-server level, or from a user-

accessible file-server. Controlling sensitive data at a central-server

prevents it from being delivered to an area where it can be compromised.

Beyond this, DM capabilities may include granularity in exactly what is

protected -- for example: by file name, file extension, file type,

component, project, workspace, or release.

There can be also granularity to control actions, such as: create, modify,

delete, view, and project managers -- plus granting role-based security to

various team members.

---- ---- ---- ---- ---- ---- ----

Again, I must advise reading (part I) the "nuts and bolts" in ESNUG 539 #4

before reading these details above.

For my comparative table of the current known DM systems, please go to the

final item here at ESNUG 539 #6.

- Dean Drako

IC Manage Campbell, CA

---- ---- ---- ---- ---- ---- ----

Related Articles

SCOOP! - Dean Drako's design and IP management survey Infographic

Nitty-gritty details to that design and IP survey Infographic

What design and verification engineers want on global projects

15 gotchas found in Design and IP data management tools (part I)

15 gotchas found in Design and IP data management tools (part II)

Dean Drako on IC Manage, Subversion, DesignSync, ClioSoft, CVS

The IP owner and verification engineer can also selectively auto-

propagate any fixes. The bug notification and fix is automatically

attached to the IP itself so that any future IP user can use it."

- from http://www.deepchip.com/items/0520-03.html

Controlled automation of these "bug interdependency management" steps can

also prevent inadvertently taping out with a known bug.

The alternative is to manually clone bugs for every derivative (or shared)

component.

---- ---- ---- ---- ---- ---- ----

6. IP REUSE SUPPORT

Our 2013 survey ESNUG 520 #1 showed that 44% of non-memory design involved

internal IP reuse. A company's ability to make its internal IP readily

available for reuse by all design teams is critical for competitiveness.

Splitting. A single IP repository (data storage location) allows your HW

design team to maintain the relationships between design files that would

otherwise be lost if split across multiple repositories. And although

splitting repositories is painful, unless your reuse database scales to

large file and directory accounts, 1000's of users, and 1,000,000's of

concurrent connections, splitting is inevitable to maintain functionality

and performance.

Tracing IP history. You maximize IP reuse if your DM system can trace where

your IP is being used across projects (designs-products), subsystems, and

by which users. Further, companies like to see how individual IP evolves

over time, in terms of design content and quality.

- A change-based DM system lets engineers see who made what changes

and to trace the history over time. For example, if someone

modified the IP, they may have changed it to a 32-bit bus, added

pipelining, and targeted a different process.

- A file-based systems makes duplicate physical copies of the IP.

The big drawback here you lose reliable, automated traceability.

The designer must first search the repository - or multiple

repositories - to find the IP copies, and then manually

determine the differences.

Searching for IP. Does your DM system publish your IP based on its

characteristics such as target process, power consumption, max frequency,

silicon validation, area? Can you also search using quality metrics like a

quality checklist status, passing functional verification, physical DRC/LVS

verification, number of open bugs, etc.?

---- ---- ---- ---- ---- ---- ----

7. PROJECT MANAGEMENT & STATUS REPORTING

In addition to managing your design data, engineering managers also want to

be able to track design activity. This requires first setting up your

project for efficient management (see "2. Configuration Management") and

then having visibility at the project/design-level to see what design

modules have been checked in and out, and how often.

Managers also want status reports and analysis, often daily. If the project

is not converging, they will then want more granular status reporting so

they can to drill down to determine which design/IP blocks are causing a

problem or project delay.

Does your DM system do this for you, and to what degree? Many DM systems

require groups to fill out spreadsheets manually to do status updates. This

in turn involves manual and error prone tasks of extracting up-to-date

information from already overburdened design team members.

One example of this that the U.S. Army, Navy, Air Force, and Marines each

have their own inventory systems for ammunition which can NOT share data

directly -- even though they have worked for decades to develop one single

database.

"A request for ammunition from the Marine Corps, for example, is

e-mailed to the Army. The e-mail is printed out and manually

retyped into the Army system because the services cannot share

data directly. Not only is this time consuming, but it can

introduce errors -- by an incorrect keystroke, for example."

- USA Today (04/28/14)

If the meta-data (e.g. revision data) in your DM system is captured in a

consistent, accurate way, your project leads will be happy. Why? Because

it means they can automatically generate reports and do trend analysis at

the top-level, plus readily see at a glance the project status of all IP

and subcomponents -- covering IP quality, open bugs and tapeout readiness.

They can even graph the trend of these metrics from version to version.

---- ---- ---- ---- ---- ---- ----

8. CHECK-LIST DRIVEN ACCEPTANCE FLOW

Last year's 2013 IP Reuse study ESNUG 520 #1 referenced a growing practice

for engineering groups to set up a formal process for IP development and

verification, with checklist items to track and monitor on each block; thus

tying the relevant status information of all the IP used to continuously

gauge the project's progress. A check list can apply to each stage of

design and verification to be passed.

These individual checklist guidelines can be enforced loosely or strictly,

depending on your company need. It can be for any design component.

This will encourage certain steps to be taken; for example, when a remote

design group checks in an IP, it's ready for a team at a different site and

time zone to use it the following day -- without schedule hits due to some

forgotten oversight. It also allows better quality control and visibility

into design progress, and correspondingly, the ability to assign resources.

Does your DM system directly integrate checklists? With automatic updates

tied to each design element? Or is it done outside the system by hand on

an Excel spreadsheet? And for for IP reuse: is the state of your design

checklist directly linked to the state of your IP, so that it's always

up-to-date?

---- ---- ---- ---- ---- ---- ----

9. LINKING/IMPORTING IP & DESIGN DATA FROM OTHER SYSTEMS

Our 2014 Design and IP Management survey (ESNUG 539 #1) showed that 55% of

companies have at least two different DM systems. Further, the majority

of those with multiple DM systems want better integration between them.

(One example is when a digital design team wants to use design elements

from the analog team.)

One approach to have different DM systems "talk" is to use a virtual tree

design. In such a system it is possible to perform multi-DM-system

configuration management by mapping individual DM system tree structures

into the virtual representation. Users can then register bindings into

the virtual object (protocol, authentication, tree structure, release info)

which allows users to pull content from multiple DM systems in a

transparent manner.

Another method is to manually copy your design data from your source DM

system and check it into your destination DM system. A drawback is that

designers then lose the link to the active design status, breaking the

audit trail.

---- ---- ---- ---- ---- ---- ----

10. PROPERTIES ENCAPSULATED IN IP

By encapsulating internal and 3rd party IP properties hierarchically and

organizing them in an easily searchable manner, everyone has immediate

access to all your IP's data, metadata, constraints and design history

all in one place. To encourage verification reuse, verification info

like testbenches, assertions and results, can also be encapsulated.

Because IP evolves dynamically over time -- often in parallel with chip

development -- it should be continuously updated.

Does your DM system allow you to encapsulate IP properties or design status

data? If yes, can it maintain the inherited hierarchy for the properties?

---- ---- ---- ---- ---- ---- ----

11. GLOBAL DATA CONSISTENCY / LOCAL CACHING

Global data consistency means everyone on the same project has access to all

versions of the same files plus its latest versions.

The way DM infrastructures try to get this desired result varies.

Mirrors. Some DM systems use mirrors -- or repository replicas -- for data

availability at remote sites. A drawback is that the mirrors can get out of

sync so that your master file content diverges from the remote site content;

that is, you get different results when trying to access the latest version

of a file.

With mirrors, there is an inherent synchronization overhead to ensure that

different teams get the same file version. The more mirror sites, the more

complicated this becomes and the greater the risk of error.

Caching. Some DM systems do global consistency by having a single server

maintain one global point of reference for versioned metadata and user

workspace contents. This type of DM system must use local caching to

deliver copies of design file data consistently and it must run quickly

across multiple sites.

The design file data is stored at remote sites in a local cache, while the

revision control metadata is stored at the master site. Remote queries to

the metadata should be fast since those involve a small number of network

packets. This approach also eliminates synchronization problems, even with

multiple servers.

---- ---- ---- ---- ---- ---- ----

12. METADATA CONSISTENCY / RELIABILITY

Does your DM system have a single distinct metadata repository that works

at both the IP and project level?

The goal of capturing metadata in a consistent way during design module

development is so your DM system can automatically generate reports and

trend analysis at the top level on down.

For DM systems without a centralized meta-data repository, the project

leader would need to query the status of individual files and workspaces,

which can be extremely time consuming.

---- ---- ---- ---- ---- ---- ----

13. ATOMIC TRANSACTIONS

Atomic transactions mean that all database updates associated with a given

design change are executed -- or none are. Atomic transactions prevent

inconsistent database states, for example, in case of a network disruption

where a subset of necessary updates are completed. Atomic transactions

prevent this from occurring.

Atomic transactions are necessary to prevent data corruption, which can be

painful to unravel and recover from.

Virtually all DM systems claim "transactions". However, for individual-file

based systems, which don't understand "transactions" for groups of files,

the concept of an atomic transaction, is confusing at best and difficult

to implement in a reliable and consistent manner.

---- ---- ---- ---- ---- ---- ----

14. R&D CONTINUITY DESPITE REMOTE NETWORK DISRUPTIONS

To maximize 24/7 productivity, it is ideal that designers at remote sites

are able to continue to operate productively within their project.

Distributed server architectures can tolerate transient network disconnects

to the corporate network because both metadata and data are available

locally at the remote site. It is possible to sync to the last replicated

file version, as well as perform checkouts of existing files if the

connection to the central server is lost. Once the network connection is

restored, version records are automatically re-synchronized to prevent

data corruption and version conflicts.

---- ---- ---- ---- ---- ---- ----

15. GRANULAR SECURITY

From our survey this year, security issues with file-based DM systems were

a factor for 69% of designers. Companies want to protect their key assets

such as trade secrets and IP -- plus conform to export restrictions.

On security issues, a fundamental difference between DM systems is whether

your data is controlled at one central-server level, or from a user-

accessible file-server. Controlling sensitive data at a central-server

prevents it from being delivered to an area where it can be compromised.

Beyond this, DM capabilities may include granularity in exactly what is

protected -- for example: by file name, file extension, file type,

component, project, workspace, or release.

There can be also granularity to control actions, such as: create, modify,

delete, view, and project managers -- plus granting role-based security to

various team members.

---- ---- ---- ---- ---- ---- ----

Again, I must advise reading (part I) the "nuts and bolts" in ESNUG 539 #4

before reading these details above.

For my comparative table of the current known DM systems, please go to the

final item here at ESNUG 539 #6.

- Dean Drako

IC Manage Campbell, CA

---- ---- ---- ---- ---- ---- ----

Related Articles

SCOOP! - Dean Drako's design and IP management survey Infographic

Nitty-gritty details to that design and IP survey Infographic

What design and verification engineers want on global projects

15 gotchas found in Design and IP data management tools (part I)

15 gotchas found in Design and IP data management tools (part II)

Dean Drako on IC Manage, Subversion, DesignSync, ClioSoft, CVS

Join

Index

Next->Item

|

|